Reducing Hot Water Wait Time

August 2019

Homeowners routinely complain about how long it takes for hot water to reach the tap, but the solution is easier than you think

By Tim Kampert

One of the most common homeowner complaints we hear is, "It takes forever to get hot water." The frustration and inconvenience of that wait ("lag time" in industry lingo) is often more important than the impact on their water bill from gallons of water wasted while they wait for it to heat up. But some upfront planning can significantly reduce hot water wait time.

The problem stems from builders that typically don't include standardized plumbing layouts on their construction drawings, assuming it's the plumber's job.

But the layouts I see for many homes tell me that plumbers give little thought to lag time; pipes are run the easiest routes possible rather than the shortest, including runs through attic spaces or exterior walls that expose them to seasonal heat loss or gain and potential freezing.

That practice is, unfortunately, made worse by water-saving faucets and showerheads; at lower flow rates, fewer gallons per minute can pass through them, and heated water takes longer to reach the end point. Combined with inefficient plumbing layouts, the result is even longer wait times and probably more unused water down the drain.

Point-of-use heaters located near critical fixtures and hot water recirculation pumps controlled by a switch or sensor may reduce lag time, but they're too costly for most production jobs and also can raise the homeowner's energy bills.

You can get much of the same benefit with a deliberate plumbing layout designed to reduce pipe runs from a centralized water heater. It adds nothing to job cost and requires fewer materials, while mitigating a lot of complaints.

Centralize the Water Heater

The most obvious step the builder can take to shorten plumbing runs is to relocate the water heater from the garage or attic (where a leak can be catastrophic) to a small, centrally located closet or perhaps under a central staircase.

This placement may reduce the amount of storage capacity in the home, but consider whether losing a bit of closet space is worth the price of unused water and long lag times for your homebuyers. You may find the benefits of a centralized water heater to be a sales advantage.

Rethink the Plumbing Layout

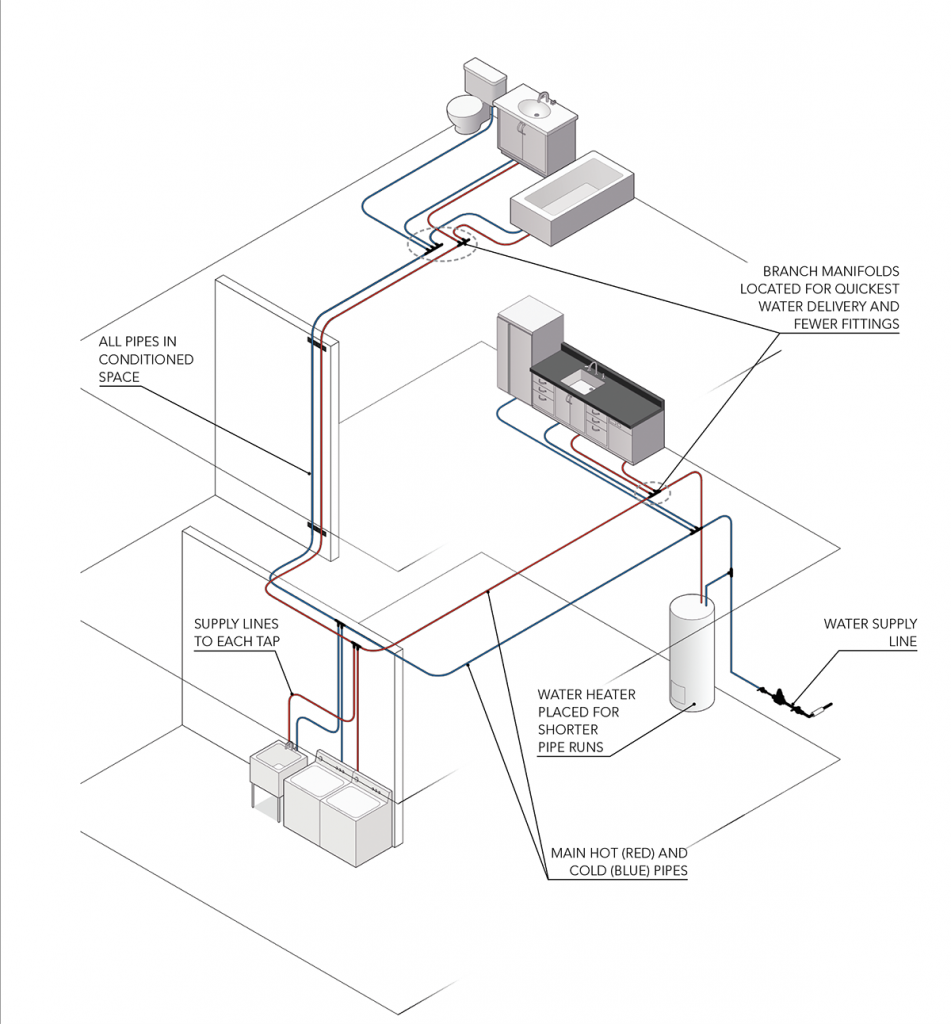

The other key is to create plumbing layouts intended to reduce wait time. In addition to containing the entire system in conditioned space to help minimize heat loss/gain and freezing potential, the plans need to show the location of all pipes running through the framing members.

With that, supply runs should be routed as close as possible to the hot-water fixtures to help shorten the drops that branch off from the main lines. Then the plumber needs to follow that plan, and you need to verify it in the field.

PEX plumbing systems, which command a large portion of the new-home market, allow drops of varying lengths from multiport tees placed close to fixture groups (see diagram, above). Designed correctly, this approach shortens pipe runs and reduces the number of fittings, which leads to even shorter wait times and fewer potential leak points than standard trunk-and-branch layouts.

Bottom line: Centralize the water source, put the pipe only in conditioned space, and intentionally design the plumbing layout to minimize pipe runs, all of which will save you time, money, and headaches in the long run.

Source: PROFESSION BUILDER